Efficiency Enhancing Project (VAP) Supports and CycloJet Units

Our country has a target of reducing “the energy we consume per unit of national income (international definition of energy intensity)” by 15% by 2023.

In this context, Efficiency Improvement Projects (EIP) are supported by the Ministry of Energy and Natural Resources.

30% of the projects up to 1.000.000 TL budget are given grant support in this context.

Participation can be made with 5 projects each year.

( http://www.enerji.gov.tr/tr-TR/Sayfalar/Enerji-Verimliligi-Destekleri )

Dedusting systems,

In many enterprises, the energy consumed by dust collection systems accounts for up to 20% of the total factory energy.

The energy consumption of dust collection systems is driven by 2 factors,

- Ventilator electric energy,

- Electricity consumption through the compressor due to compressed air consumption.

In addition, the quality of the filter bags and whether they can be cleaned properly or not can increase or decrease the fluid resistance, and these factors also affect the electrical energy consumed.

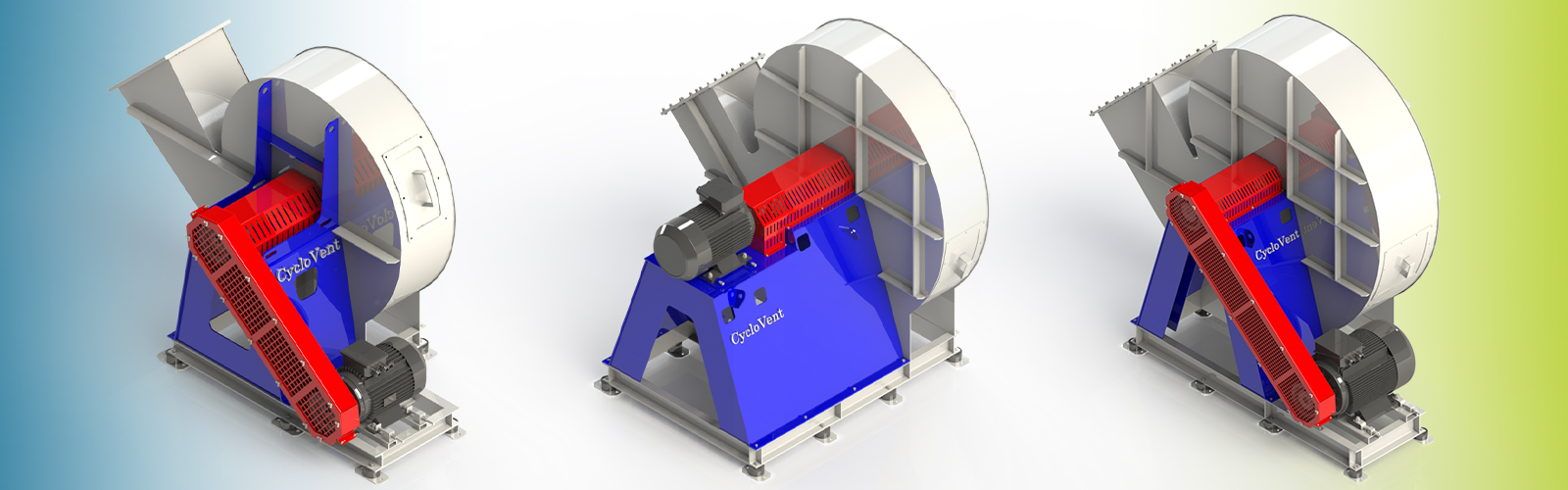

CycloJet Units, produced with Asel Teknik&Industrial patent, reduce energy consumption by

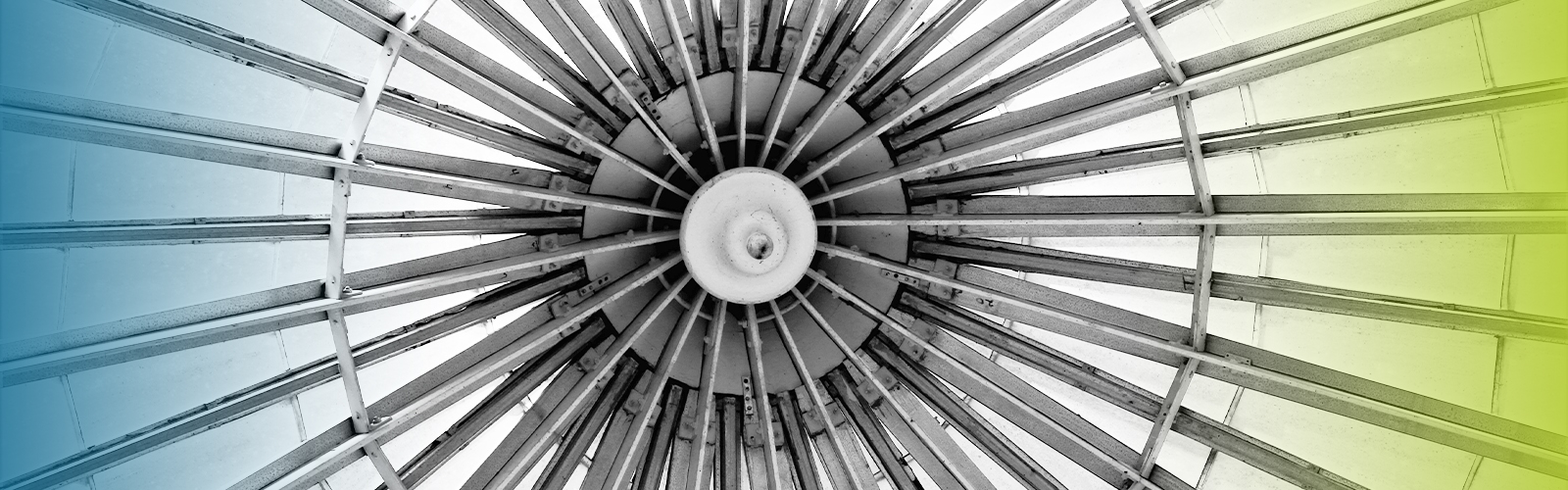

- It has a unique double-walled construction with a separator cyclone on the outside and a bag filter on the inside. This structure is tailor-made by designing it specifically for each mineral with fluid simulations. In this way, 40% of the average dust is retained in the cyclone wall without ever reaching the bags. Thus, the bags are much less dirty, have low air permeability resistance and consume less electricity,

- The patented “CycloJet Smart” Intelligent Control System continuously monitors the flow rate drawn from the plant and corrects the fan speed to keep it constant. This results in energy savings of at least 35%,

- The CycloJet Smart software balances the compressed air consumption according to the flow rate being withdrawn from the plant. In this way, only as much compressed air is consumed as required, resulting in significant savings,

In this way, a sample 90,000 Nm3/h capacity dedusting system in Kütahya consumed 866,000 kW/year of energy instead of 1,354,000 kW/year.

Dust collection units with reduced efficiency can be replaced with CycloJet units and can be evaluated within the scope of “Efficiency Improvement Project”.