The Key to Efficiency in Industrial Facilities: Dust Collection Systems and How They Work

The Invisible Risk in Production

In many industries such as metal processing, foundries, ceramics and porcelain manufacturing, cement, food, and chemical sectors, production processes inevitably generate airborne particles. These microscopic dusts pose a serious threat to employee health and negatively impact machine precision and product quality. At this point, professional solutions that act like the “lungs” of the facility and create clean air zones come into play: Industrial Dust Collection Systems.

In this article, we will examine step by step how a dust collection system works and the role of modern solutions offered by expert companies like Asel Teknik.

What is a Dust Collection System?

A dust collection system is an integrated engineering system that captures dust, smoke, and other airborne particles at the source during production, transports them through ductwork, separates them from the air with high efficiency, and safely stores them. Its primary purpose is to clean the air in the working environment, ensure compliance with legal limits, protect employees from occupational diseases (especially serious ones such as silicosis), and most importantly, eliminate safety risks caused by combustible/explosive dusts.

Basic Operating Principle: Maximum Efficiency in 5 Steps

The success of a dust collection system is based on a systematic process in which each step is correctly designed.

Step 1: Source Capture (Maximum Suction Power)

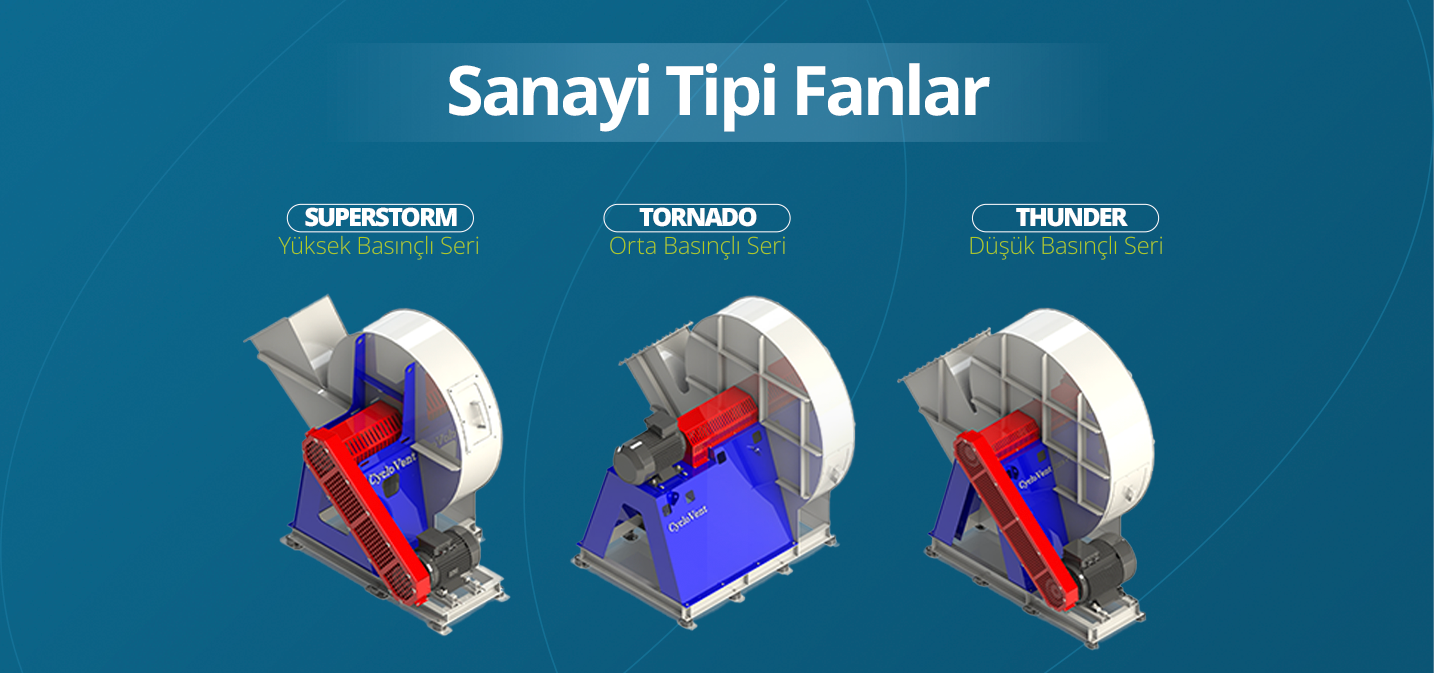

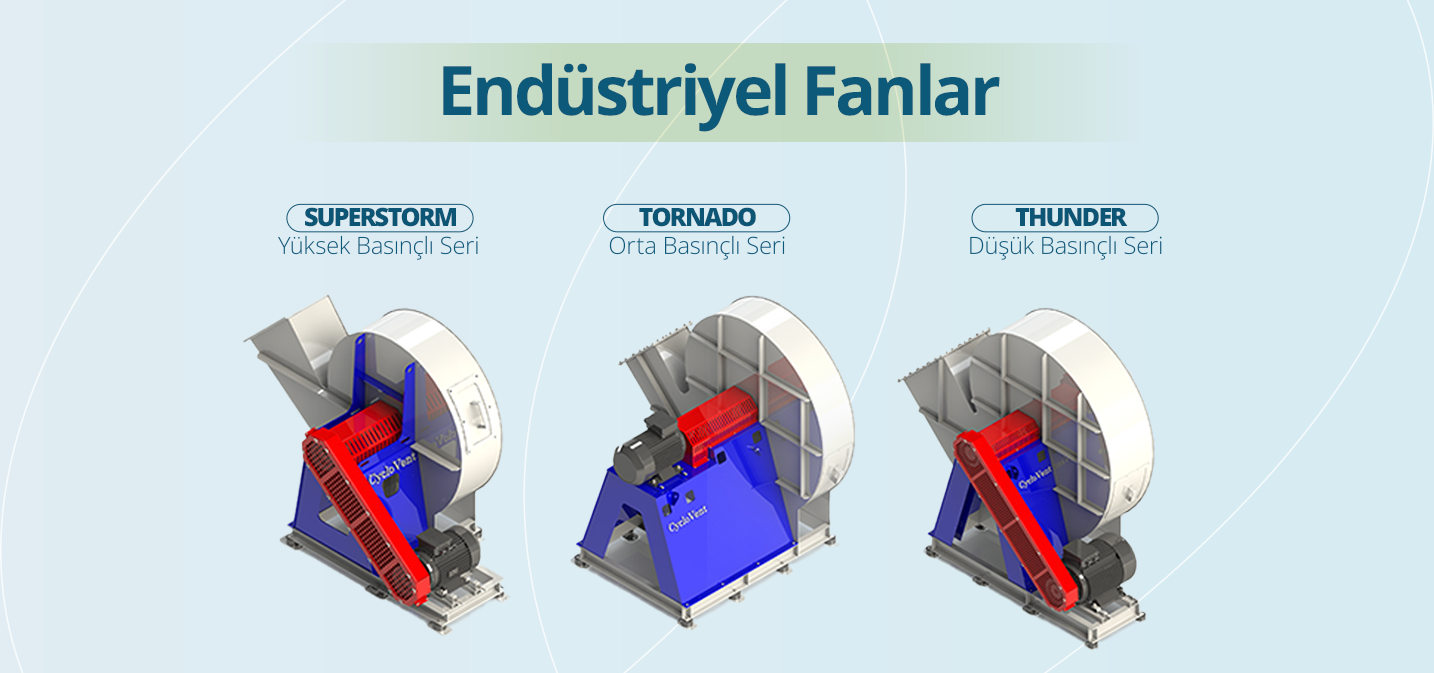

Everything starts at the point where the dust is generated. A glazing booth, a mill, a pressing machine, a kiln outlet, or a packaging line… It is crucial to capture the dust before it spreads into the environment. The vacuum effect created by the high-pressure fan (extractor) at the heart of the system instantly draws in the dust and polluted air through specially designed hoods or articulated suction arms. Effective capture is the foundation of system efficiency.

Step 2: Transportation (Optimized Ductwork)

The dust-laden air captured at the source is transported to the main filter unit through a duct network calculated according to the particle structure and density. In Asel Teknik’s engineering, these ducts are designed to ensure that materials are transported without settling and without energy loss, maintaining optimal air velocity. This prevents system clogging and increases energy efficiency.

Step 3: Separation and Filtration (Asel Teknik Technology)

The dust-laden air transported through the duct reaches the filter unit—the brain of the system. The aim here is to separate dust from the air with over 99% efficiency. At this stage, different technologies are used according to need:

- Cyclone Separators: Especially used as a pre-separator in processes involving dense and large particles (e.g., raw material preparation), to reduce the load on the main filter. High-efficiency cyclones provided by Asel Teknik use centrifugal force to separate coarse particles from the air, increasing the system’s overall life and efficiency.

- Jet Pulse Filters: These are the backbone of modern dust collection. At this stage, Asel Teknik’s Jet Pulse Bag and Cartridge Filter units come into play. Dust-laden air hits the outer surface of specially selected filter materials (bag or cartridge). As the air passes through micron-sized pores, dust particles are retained on the surface. Choosing the right filter is crucial, especially for dangerous particles such as fine silica dust in the ceramics industry, and is determined according to the chemical and physical structure of the dust.

Step 4: Automatic Filter Cleaning (Continuous Performance)

The dust cake accumulated on the surface of the filters creates resistance against airflow. To overcome this resistance, the filters must be cleaned regularly. Asel Teknik’s systems use advanced Pulse-Jet (Compressed Air Cleaning) technology to automate this process. Valves connected to an electronic timer blow high-pressure air into the filters at intervals of seconds, shaking off the accumulated dust and sending it into the collection hopper below. This process runs continuously while the facility is still operating.

Step 5: Collection and Safe Disposal

The dust shaken off the filters accumulates in the conical hopper beneath the system. From there, it is discharged via air-sealed rotary valves or sliding gates into big bags, barrels, or screw conveyors. Asel Teknik ensures the dust is safely and easily disposed of through efficient airlocks and hopper designs integrated into the system.

The cleaned air at the end of the process is then either released into the atmosphere in compliance with standards or returned to the production area after conditioning to reduce energy costs.

Why a Professional System is Essential

- Occupational Safety: Many particles, such as metal, chemical, or food dust, pose explosion and fire risks under the right conditions. Systems installed by companies like Asel Teknik, which provide ATEX-certified equipment, help manage this critical risk.

- Employee Health: Especially in the ceramics and porcelain industries, inhaling silica dust causes fatal occupational diseases such as irreversible silicosis. Clean air protects your most valuable investment: your human resources.

- Production Quality and Efficiency: A clean environment extends the lifespan of sensitive machinery, improves the quality of surface processes like glazing and decoration, and minimizes production downtime due to malfunctions.

- Legal Compliance: To pass inspections by the Ministry of Environment, Urbanization and Climate Change and the Ministry of Labor without issues, it is essential to comply with legal emission limits.

Industrial dust collection is not just a fan and a few pipes. It is a serious engineering application that requires site inspection, correct project design, high-quality equipment selection, and turnkey installation. When you need a dust collection system, working with an expert and reputable solution partner like Asel Teknik ensures that you get full value from your investment and take a crucial step for the future of your facility.