Fans

Dedusting Systems

The First Step to Sustainable Performance and Economy

Ventilators…

One of the most important aspects of the design of a dust collection / ventilation system is the ventilators…

When it is incorrectly calculated/selected, it is one of the biggest factors in the inability to provide performance or inefficient operation throughout the life of the system.

A fan operating at less than the required flow rate already means that dust cannot be collected.

A fan that operates at a higher flow rate than necessary can cause many problems, from the waste of your most valuable product to the perforation of dust collection ducts.

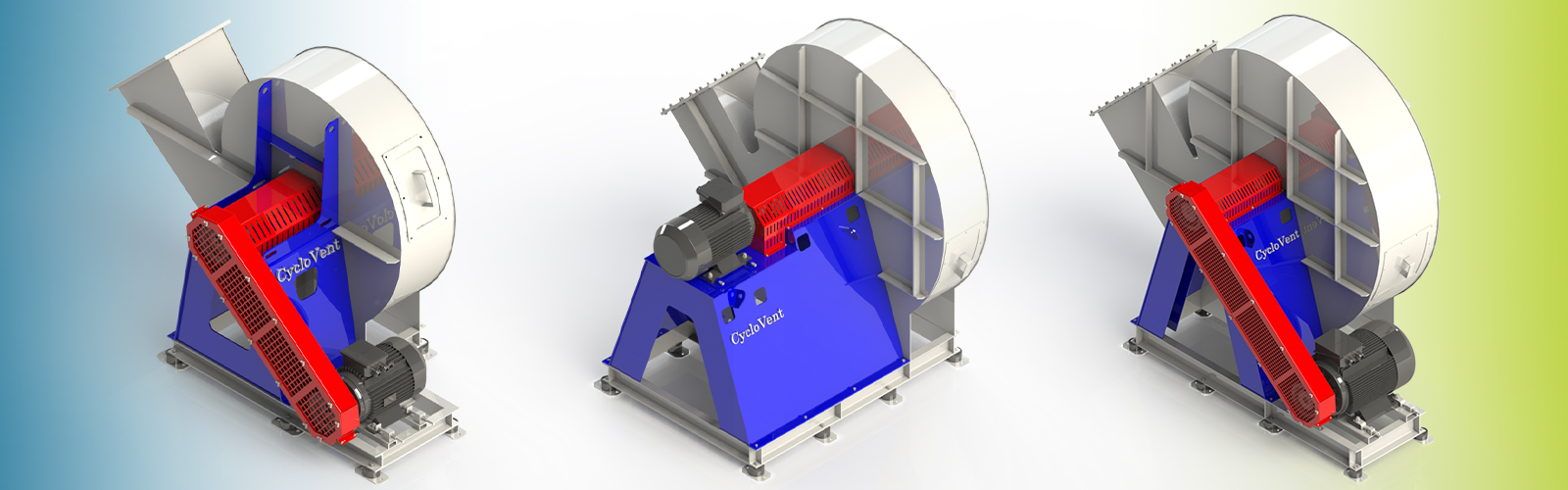

The fan shown in the graphic on the side;

Is it at 2,000 m3/h flow capacity?

Is it at 1,000 m3/h flow capacity?

500 m3/h flow capacity?

All true or all false…

Flow rate alone is a meaningless term for a fan.

For it to be meaningful, it has to be accompanied by the question at least at what pressure?

If you have calculated losses for a system and calculated a flow rate to overcome this resistance, but the losses or the fan design is not correct, nothing will go right. In short, you will be on the wrong left or right side of the graph. So either you will not be able to collect the dust with too little flow, or you will lose product with too much flow.

Therefore, it is not possible to build a dust collection system with high performance and high energy efficiency with a poorly engineered fan selection.

Do you doubt this?

Please compare the filtered air flow rate from the chimney with the fan label value,

Or check if your product is included in the dust analysis you collect.

Many people report not getting even half of the fan label value and finding product in at least 20% of the filter dust…

Other parameters related to sustainable performance and efficiency will be continued in the next issues…