CycloJet TOR 252

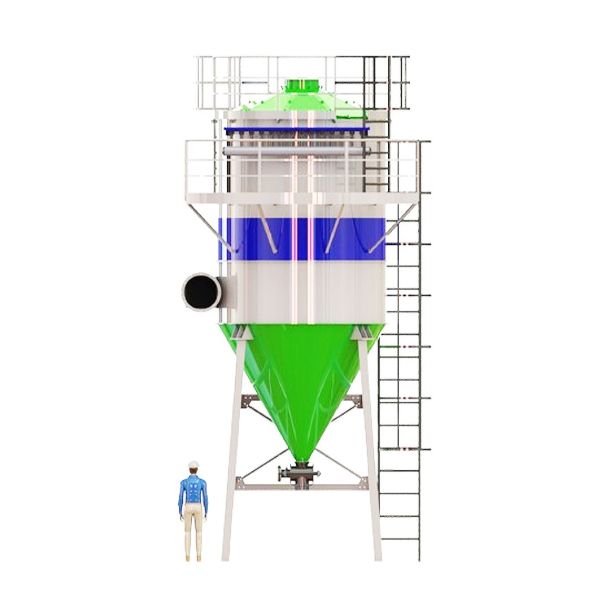

Operating on the Jet Pulse principle, it provides maximum efficiency in a minimal space. With a fast and easy installation process, it operates silently and without emissions right next to the facility, standing out with its design that does not require a chimney. Thanks to cartridges specifically designed for each environment or process, it covers capacity ranges from 9,000 Nm³/hour to 18,000 Nm³/hour, and with its unique cyclonic structure, it directs particles larger than 45 microns to the collection cone before reaching the filter elements.

CycloJet TOR 252

The capacity information and general dimensions are provided in the “documents” section.

It operates on the Jet Pulse principle.

It is a method of cleaning filters with compressed air pulses. This ensures that the filters have a long service life and the system operates at high efficiency.

Compact Footprint and Quick Installation

Since space is limited in industrial environments, this feature provides a significant advantage.

Quiet and Emission-Free Operation

Thanks to this feature, the system can be positioned within the facility, even right next to the machine, because it does not create noise pollution and does not emit harmful emissions.

Custom-designed filter elements

Wide Capacity Range

With a capacity ranging from 9,000 Nm³/hour to 18,000 Nm³/hour, it can meet the needs of businesses of different sizes.

Cyclonic Structure

It ensures that particles larger than 45 microns are collected before reaching the filter elements, which extends the filter life and provides energy savings.

Low Energy Consumption

Low energy consumption for both compressed air and fans reduces operating costs.

User-Friendly Automation

The fully automatic control panel provides convenience for users and maintenance personnel. The system switches to automatic cleaning mode when the machine it serves stops and prepares for the next operating period.

Cartridge Dust Collection Units

CycloJet TOR 252

The user- and maintenance-friendly fully automatic automation panel simplifies system operation; when the machine it serves stops, it switches to automatic cleaning mode to prepare for the next period. Filter elements can be easily replaced within half an hour.

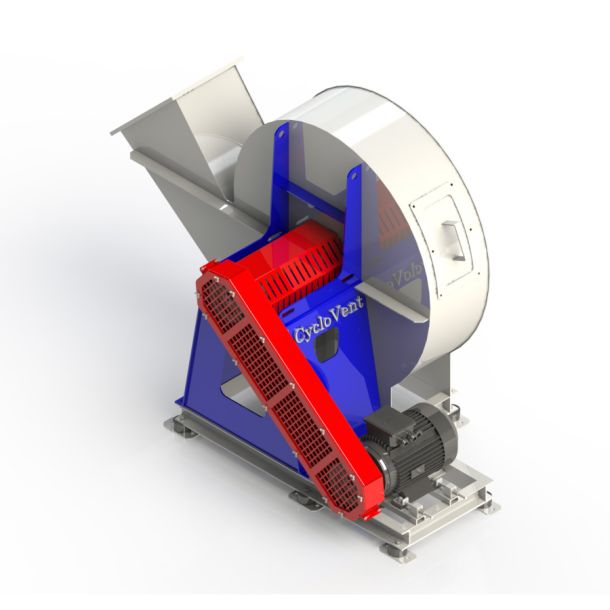

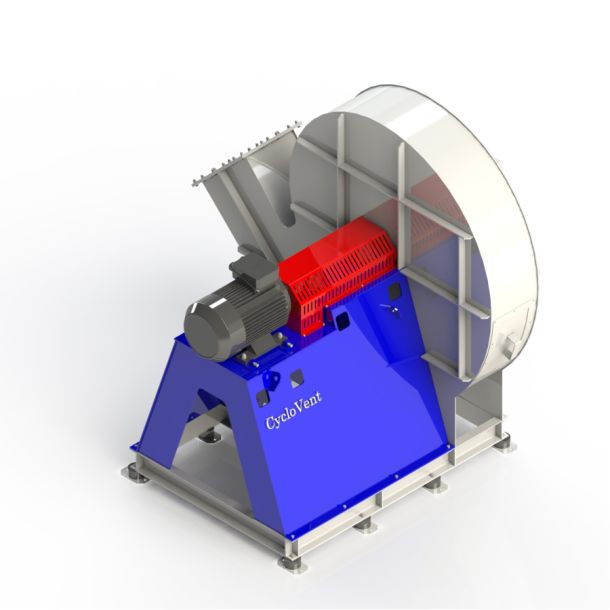

CycloVent Industrial Fans with Volute Design

CycloJet Dust Collection Systems

CycloVent Industrial Fans with Volute Design

CycloVent Fans are designed to meet the needs of our customers with products that reflect Asel Teknik‘s innovative spirit, offering high efficiency and superior silence. Our fans are equipped with specially developed software that reduces energy consumption without compromising performance. Knowing the critical importance of the volute design, we shape every detail aiming for perfection. This not only guarantees high performance and quiet operation but also ensures energy savings. With CycloVent, say goodbye to performance losses, increased noise, and unnecessary energy consumption. By acting on the principle of ‘High Efficiency = Minimum Noise,’ we extend the life of your fans, provide energy savings, and offer a peaceful working environment. In your search for comfort and efficiency, meet CycloVent.

References

Please Contact Us!

News

Subscribe Now!

Stay Informed About the Latest Developments in the Industry!

History of Fans

Throughout history, fans have carried a meaning beyond being practical tools for providing coolness on hot summer days.

Documents

CycloJet & Cyclovent Dust Removal and Vacuum Systems Guide | Download |

Installation and Operating Notes (Dust Removal Units) | Download |

Radius-Resistance Relationship | Download |

Dust Collection Unit Selection Chart | Download |

TOR Series Selection Chart | Download |

CycloJet Series Dimension Table | Download |

CycloJet Capacity Table | Download |