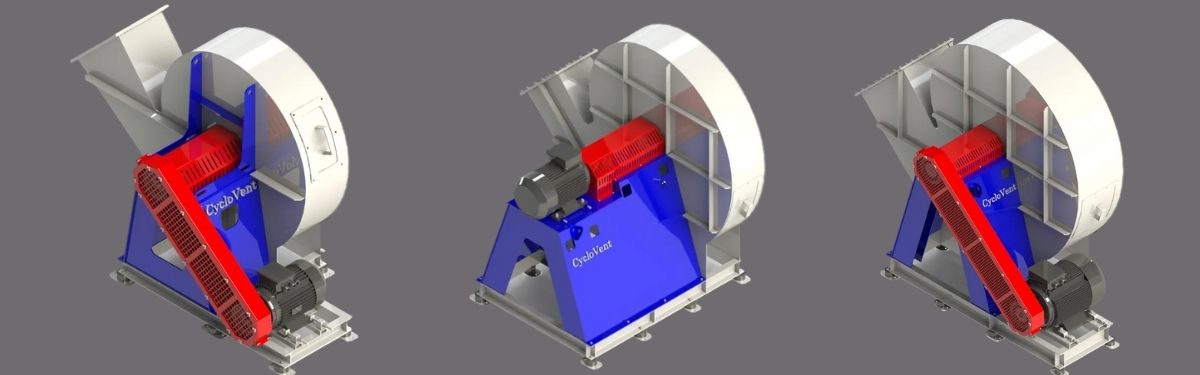

Radial fans are crucial equipment used widely in various industrial and commercial applications. The types and characteristics of these fans vary to suit specific functions and applications. Radial fans, in particular, hold an important place in this category. In this article, we will examine the different classes of radial fans, their effectiveness in various applications, and their features related to quiet operation and energy efficiency.

What is a Radial Fan?

Radial fans are a type of fan used to provide airflow. In other words, the air is pushed out from the rotor of the fan. These fans are typically preferred for applications requiring high pressure. Radial fans are divided into three main classes: Straight Radial, Backward-Curved, and Forward-Curved.

Straight Radial

Straight radial fans have blades that extend straight outward from the center. Radial blades are often used in particle-laden gas flows because they are less sensitive to solid matter buildup, but they are generally characterized by higher noise output. Straight radial fans operate at high speeds, low volumes, and high pressures and are frequently used in vacuum cleaners, pneumatic material handling systems, and similar processes.

Backward-Curved

Backward-curved blades are angled opposite to the direction of rotation of the fan wheel. Smaller fans may have straight, non-curved backward blades. Larger backward-curved fans feature blades with airfoil profiles that mimic backward curves, but both designs offer good operational efficiency with relatively economical construction techniques. These fans are designed to handle gas flows with low to moderate particle loading. They can be easily equipped with abrasion protection, although certain blade angles may be prone to solid matter accumulation. Backward-curved fans are generally heavier than their forward-curved counterparts because they operate at higher speeds and require a more robust structure.

Backward-curved fans can have specific speed ranges but are most often used in applications requiring medium flow rates and high pressure, such as air handling units. They are more energy-efficient than radial and forward-curved fans, making them a cost-effective alternative for high-power applications.

Forward-Curved

Forward-curved blades are angled in the direction of the fan’s rotation. These blades are particularly sensitive to particles and are typically designated for clean air applications, such as in air conditioning systems. Forward-curved fans are used in applications requiring high static pressure where an axial fan with a single blade is inadequate or where a centrifugal fan’s small size is needed but the noise characteristics of a backward-curved fan would be disturbing. They can provide lower airflow but achieve a higher increase in static pressure compared to an axial fan with a single blade. They are commonly used in fan coil units. Forward-curved fans are less efficient compared to backward-curved fans.

Quiet Operation and Energy Efficiency

At ASEL Teknik, we are pioneers in developing systems for radial fans that ensure quiet operation and energy efficiency. These systems feature high-efficiency motors, aerodynamic designs, and advanced control algorithms. As a result, the fans operate quietly and efficiently, minimizing energy consumption.

Applications

Radial fans, with their various classes, are ideal for different applications:

- Ventilation Systems: Both straight and forward-curved radial fans, along with snail designs, can be used in ventilation systems in buildings and industrial facilities.

- Air Conditioning Systems: Particularly straight and forward-curved radial fans are used for air circulation in air conditioning systems.

- Industrial Processes: Backward-curved radial fans are preferred in industrial processes requiring high pressure.

- Cooling Systems: Forward-curved radial fans can be used to enhance airflow in cooling systems.

Radial fans, categorized into different classes, cater to various application areas. The straight, forward-curved, and backward-curved designs of radial fans are tailored to meet specific pressure and flow requirements. Systems that provide quiet operation and energy savings are essential features of modern fans.