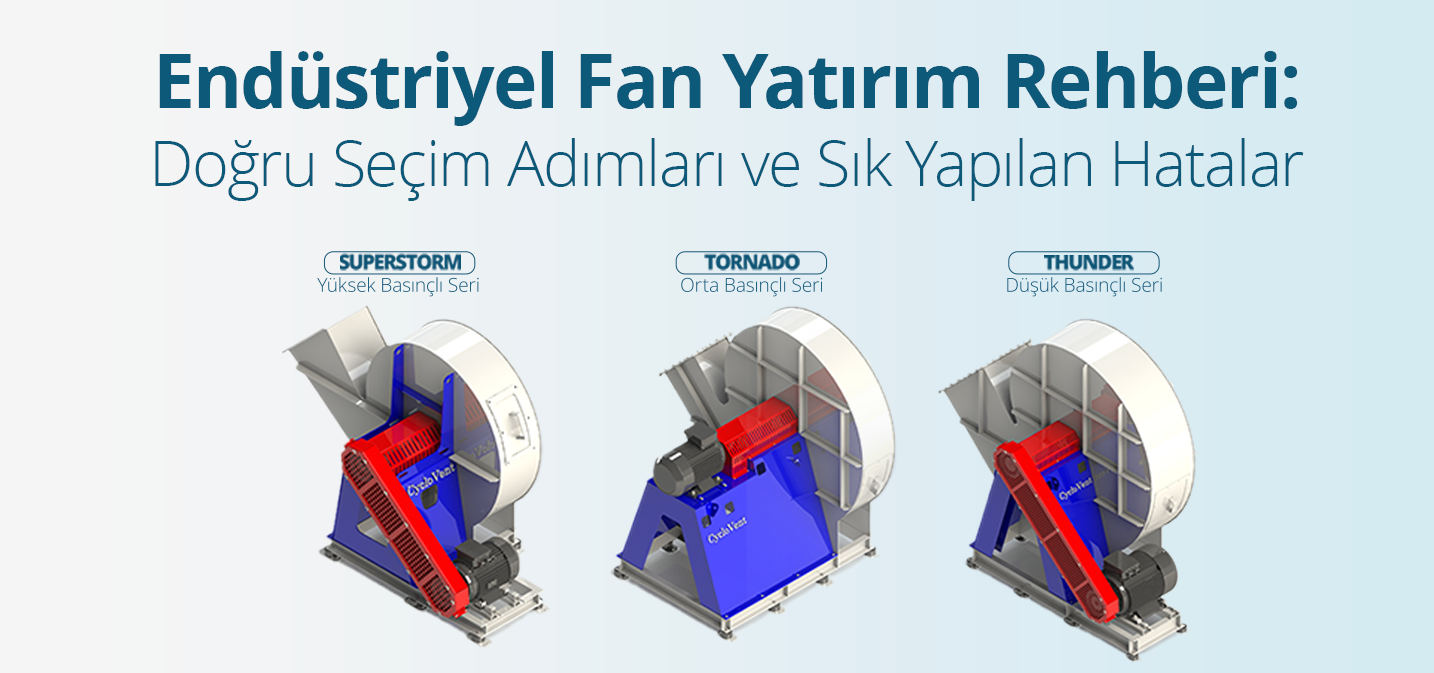

Industrial Fan Investment Guide: Correct Selection Steps and Common Mistakes

Choosing the right fan in industrial facilities is fundamental to your system’s efficient operation. This critical decision directly affects every stage of your operation, from energy costs and production quality to occupational safety and maintenance expenses. An incorrect fan selection, however, can lead to serious and costly problems such as high energy bills, insufficient performance, unexpected breakdown stops, and even safety risks.

📌 So, how will you choose the right fan that will more than pay for your investment?

As Asel Teknik, in this guide prepared with our field experience, we have compiled all the critical steps of a fan investment and the common mistakes you should avoid.

1. Clarify Performance Criteria: Airflow, Pressure, and Efficiency

First and foremost, you must define what the fan needs to do, using numbers.

- Air Volume/Flow Rate (m3/h): Determines how much air needs to be transported through your system. This value is calculated based on the size of the area, the process requirements, and ventilation standards.

- Static Pressure (Pa): The resistance the fan must overcome to push air through obstacles such as filters, ducts, elbows, and louvers.

- Common Mistake: Underestimating the pressure requirement by only looking at the pipe diameter, which causes the fan to fail to deliver the desired airflow.

- Efficiency (%): One of the most critical values, showing how much of the energy the fan receives from its motor is used to move the air. A high-efficiency fan does the same job using less energy.

2. Application-Specific Analysis: Impeller Type and Material Selection

After the theoretical values are determined, the fan’s working location and manner must be analyzed.

Impeller Type:

The characteristic of the air to be transported determines the fan impeller (blade) type.

- Clean Air: Backward-curved radial fans offer high efficiency.

- Dusty, Particulate Air: Flat or radial-bladed fans that prevent material buildup are more suitable.

- High Volume, Low Pressure Air: Axial fans are ideal for general ventilation.

- Common Mistake: Choosing an impeller type with high aerodynamic efficiency but one that can easily clog in a dusty line, leading to continuous shutdowns and maintenance costs.

Material Selection:

The conditions of the working environment directly determine the fan’s lifespan.

- Abrasive Environments: Wear-resistant materials like Hardox.

- Humid and Chemical Environments: Stainless steel or specially epoxy-coated fans.

- Common Mistake: Ignoring the risk of corrosion and choosing a standard steel fan, which causes the equipment to be scrapped much sooner than expected.

3. Look Beyond the Initial Cost: Total Cost of Ownership (TCO)

Professional buyers focus not only on the fan’s sticker price but also on the total cost it will generate throughout its lifespan. This is called the Total Cost of Ownership (TCO).

TCO=Initial Investment Cost+Energy Expenses+Maintenance Costs

- Energy Efficiency: A high-efficiency fan (with IE3/IE4 motor) that is 10% more expensive initially can recoup the difference through energy savings within 1-2 years and save you money throughout its life.

- Ease of Maintenance: Features such as easily accessible inspection doors, replaceable wear plates, and high-quality bearings significantly reduce maintenance times and costs.

4. The Art of Correctly Reading Technical Data and Offers

When comparing quotes from different suppliers, make sure you are comparing apples to apples.

- Fan Performance Curves: Don’t just look at the maximum air flow and pressure values. Check the fan’s efficiency at your specific working point on the curve.

- Motor Power: Ensure the motor power (kW) is sufficient for your working point and is not oversized unnecessarily.

- Certifications: Especially in environments with flammable and explosive materials, the fan must have ATEX certification which is a legal requirement and a vital safety measure. Inquire about quality documents such as ISO standards.

Buy a Solution, Not a Fan

Choosing the right industrial fan is much more than selecting a single product; it is an investment in the efficiency and safety of your process. By following the steps above and avoiding common mistakes, you can make the most correct and profitable decision for your business.

As Asel Teknik, we don’t just offer you a fan quote. We analyze your application on-site, correctly determine your needs, and offer you the most suitable engineering solution by considering factors like energy efficiency and ease of maintenance that will reduce your Total Cost of Ownership (TCO). Don’t risk your investment, consult our expertise.