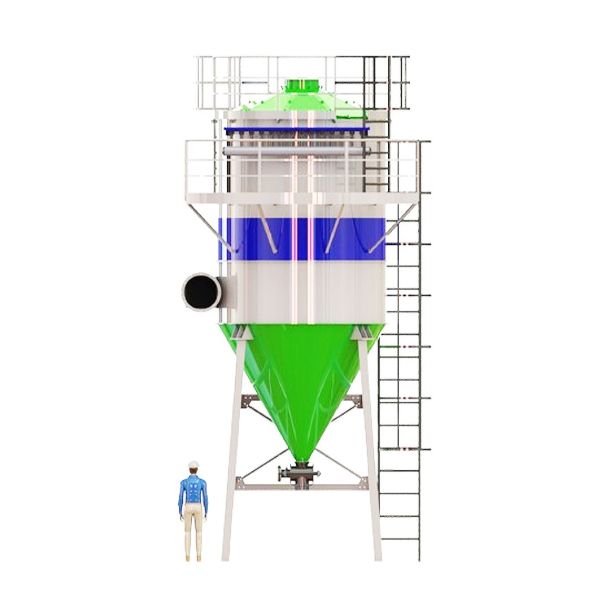

CycloJet Dust Collection Units

Reliable and Innovative Partner in Industrial Dust Control: Asel Teknik

Reliable and Innovative Partner in Industrial Dust Control: Asel Teknik

-

Airborne Dust Collection Systems

During production, fine particles that mix into the air threaten employee health and create an explosion risk. CycloJet solutions effectively capture these particles, keeping the ambient air clean and the breathable area safe. These systems provide high performance, especially in areas with continuous dust generation, such as crushers, belt conveyors, and packaging units. -

Floor Sweeping Systems

Dust doesn’t just stay in the air; it also accumulates on the floor. CycloJet’s floor sweeping systems are integrated with the central dust collection system to vacuum up dust that has settled on the ground. This offers an ergonomic and hygienic cleaning solution by minimizing manual contact. -

Waste Collection Systems

The effective collection of solid waste and coarse material residue generated along the production line is critical for occupational safety. The integrated waste collection systems provided by CycloJet ensure that solid waste and dust are transported without issues. These systems help maintain order in production areas while also contributing to automation.

Jet-Pulse Technology and Low Maintenance Requirement

Frequently Asked Questions About Industrial Dust Collection Systemsv

The system consists of five main steps:

Capture at the Source: Dust is immediately drawn in at the point of origin by the vacuum created by a fan, using hoods or articulated arms.

Conveyance: The captured dusty air is transported at an optimal speed through a calculated network of pipelines to the main filter unit.

Separation and Filtration: The dusty air is separated from the clean air with high efficiency (over 99%) inside the filter unit (such as Cyclone or Jet Pulse Filters).

Automatic Filter Cleaning: The dust accumulated on the filter surface is automatically cleaned by a blast of compressed air using Pulse-Jet technology.

Collection and Safe Disposal: The dust that falls off the filters accumulates in a hopper and is safely transferred to big-bags, barrels, or conveyor screws using equipment like rotary valves.

Cyclonic separators, especially in processes with dense and large particles, act as a pre-filter by separating coarse particles from the air using centrifugal force. This reduces the load on the main filter and extends its lifespan.

Jet Pulse Filters, on the other hand, are the main unit of modern dust collection; they capture micron-level particles with high efficiency by passing the dusty air through special filter materials (bags or cartridges).

When needed, both can be used together to increase system efficiency.

Professional dust collection systems offer many advantages for businesses: Workplace safety (reducing explosion/fire risk, ATEX compliance), employee health (preventing occupational diseases, clean working environment), production quality and efficiency (extending machine lifespan, increasing product quality, reducing breakdowns), and legal compliance (adhering to emission limits).

Industrial dust collection is more than just supplying equipment; it is a turnkey engineering application that includes site discovery, correct project design, industry- and dust-specific equipment selection, and quality installation. Working with firms that are experts in their field and have strong references ensures that the system is correctly designed, operates with high efficiency, complies with legal requirements, and provides a return on investment. The wrong system selection or installation can create inefficiency, high energy consumption, legal problems, and health/safety risks.

Designed by ASEL, the CycloVent Industry – Radial Fans can operate quietly and with high efficiency.

With the goal of producing machines that operate with sustainable performance, Asel Teknik has always prioritized quality and innovation. The company continually invests in research and development, seeking innovative solutions to improve production processes and materials used. Asel Teknik also prioritizes sustainability principles such as environmental sensitivity and energy efficiency during the design and manufacturing stages of its products, aiming to achieve a leading position in its industry.

Volute Design with CycloVent Fans

CycloVent Fans are designed to meet the needs of our customers with products that reflect Asel Teknik‘s innovative spirit, offering high efficiency and superior silence. Our fans are equipped with specially developed software that reduces energy consumption without compromising performance. Knowing the critical importance of the volute design, we shape every detail aiming for perfection. This not only guarantees high performance and quiet operation but also ensures energy savings. With CycloVent, say goodbye to performance losses, increased noise, and unnecessary energy consumption. By acting on the principle of ‘High Efficiency = Minimum Noise,’ we extend the life of your fans, provide energy savings, and offer a peaceful working environment. In your search for comfort and efficiency, meet CycloVent.

References

Please Contact Us!

News

-

Engineering Power and Innovation Vision Registered with Our Patent

Engineering Power and Innovation Vision Registered with Our Patent -

CYCLOJET WP-21 Vacuum Garbage Collection Machines on the Road for Basra Municipality in Iraq

CYCLOJET WP-21 Vacuum Garbage Collection Machines on the Road for Basra Municipality in Iraq -

Central Vacuum System Delivered to Yeniköy Kemerköy Thermal Power Plant

Central Vacuum System Delivered to Yeniköy Kemerköy Thermal Power Plant -

Cyclojet Tor 126 Dust Collection Products Exported to Erbil, Iraq

Cyclojet Tor 126 Dust Collection Products Exported to Erbil, Iraq -

Piromet Pyrometallurgy’s New Generation Dust Collection Unit Completed

Piromet Pyrometallurgy’s New Generation Dust Collection Unit Completed -

CYCLOJET WP 21 Export to Basra Region of Iraq

CYCLOJET WP 21 Export to Basra Region of Iraq -

Kütahya Provincial Health Director and Deputies Visited Asel Teknik

Kütahya Provincial Health Director and Deputies Visited Asel Teknik -

Our System Designed For The Refractory Industry Has Been Commissioned

Our System Designed For The Refractory Industry Has Been Commissioned

Subscribe Now!

Stay Informed About the Latest Developments in the Industry!

History of Fans

Throughout history, fans have carried a meaning beyond being practical tools for providing coolness on hot summer days.