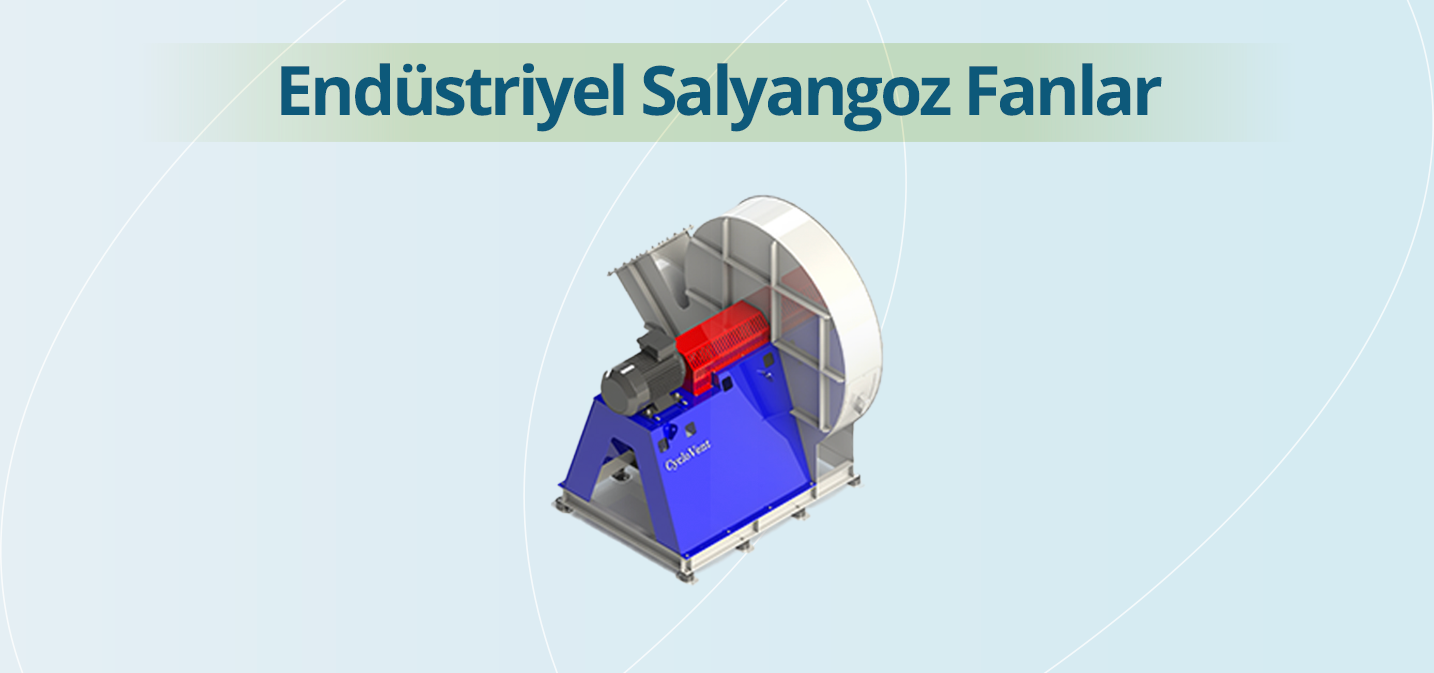

Industrial Volute Fans

Industrial ventilation systems play a critical role in managing air flow, improving air quality, and ensuring energy efficiency in large facilities. One of the most important components of these systems is industrial volute fans. Especially preferred in applications requiring intense airflow and high-pressure demands, volute fans are indispensable for the efficient operation of industrial plants. In this article, you will find detailed information about the features, advantages, and industries where industrial volute fans are used.

What is an Industrial Volute Fan?

An industrial volute fan is a high-performance type of fan used for air transportation and ventilation processes in industrial environments. It gets its name from its spiral-shaped casing, resembling a volute shell. This spiral structure allows the air to move more efficiently within the fan, enabling the production of high pressures and flows.

Working Principle of Volute Fans

Volute fans typically have a motor-driven impeller. When the impeller rotates, air is drawn into the center of the fan and progresses through the spiral-shaped casing, being expelled outward. In this process, the speed and pressure of the air increase.

Asel Teknik’s Industrial Volute Fan Solutions

Asel Teknik offers high-quality volute fan solutions for industrial ventilation systems. Products like the CycloVent series work efficiently with strong airflows and high performance, addressing the ventilation needs of industrial facilities. Asel Teknik’s volute fans can be customized to meet the air transport requirements of various industrial applications.

Industrial volute fans play a critical role, especially in areas requiring high pressure and strong airflow. Asel Teknik’s volute fan solutions ensure safe and efficient operation of industrial ventilation systems by providing efficiency, durability, and low energy consumption. These fans, manufactured with advanced technology, are successfully used in various industrial sectors.

Advantages of Industrial Volute Fans

High Pressure Production:

Industrial volute fans have the capacity to generate high-pressure airflows. This feature is particularly important for industrial applications that require air transport over long distances or airflow management in confined spaces. Volute fans meet these needs with high efficiency.

Energy Efficiency:

Industrial volute fans are designed to be energy-efficient. Brands like Asel Teknik optimize these fans to provide high performance with low energy consumption. This helps businesses reduce their long-term energy costs.

Durability and Long Lifespan:

Industrial fans are typically manufactured to withstand harsh conditions. Volute fans are designed to operate reliably and durably in tough industrial environments. Components made of stainless steel ensure that the fans function for many years without performance degradation.

Low Maintenance Requirements:

Due to their sturdy construction, industrial volute fans require minimal maintenance. With regular cleaning and periodic inspections, these fans can operate efficiently for many years, saving businesses time and money.

Applications of Industrial Volute Fans

Industrial volute fans are used in various industrial applications. These fans work effectively in areas that require high airflow and pressure. Here are some of the main applications:

Dust and Smoke Collection Systems:

In industrial production plants, it is crucial to effectively remove dust and smoke. Volute fans work with high efficiency in such applications, ensuring that ventilation systems operate smoothly.

Ventilation Systems:

In commercial and industrial buildings, the continuous renewal of indoor air is necessary. Volute fans provide effective airflow in these ventilation systems, ensuring that the air in the environment is cleaned.

Chemical and Gas Distribution Systems:

In chemical plants or gas transmission lines, volute fans safely transport gases. These fans enable the effective routing of gases by providing high-pressure airflows.

Mining and Construction Industry:

In mines, underground ventilation is critically important. Volute fans maintain oxygen levels in mines, ensuring the safety of workers.

Ceramics and Glass Industry:

In high-temperature industries such as ceramics and glass production, regulating hot airflow is crucial. Volute fans are used in hot air transport and smoke removal processes, ensuring these operations are safe and efficient.